What we do better

In order to support a sustainable lithium battery industry, we create and commercialise innovative technologies to produce lithium chemicals from waste or low-grade sources. Our two main technologies are LieNA® for processing spodumene and SiLeach® for treating lithium mica minerals.

Here’s how

We unlock value from waste or low-grade sources of hard rock lithium by investing in targeted research and development activities. Our technologies have been developed through a long-term collaboration with ANSTO (Australian Nuclear Science and Technology Organisation) Minerals.

![]()

Technology we

have developed

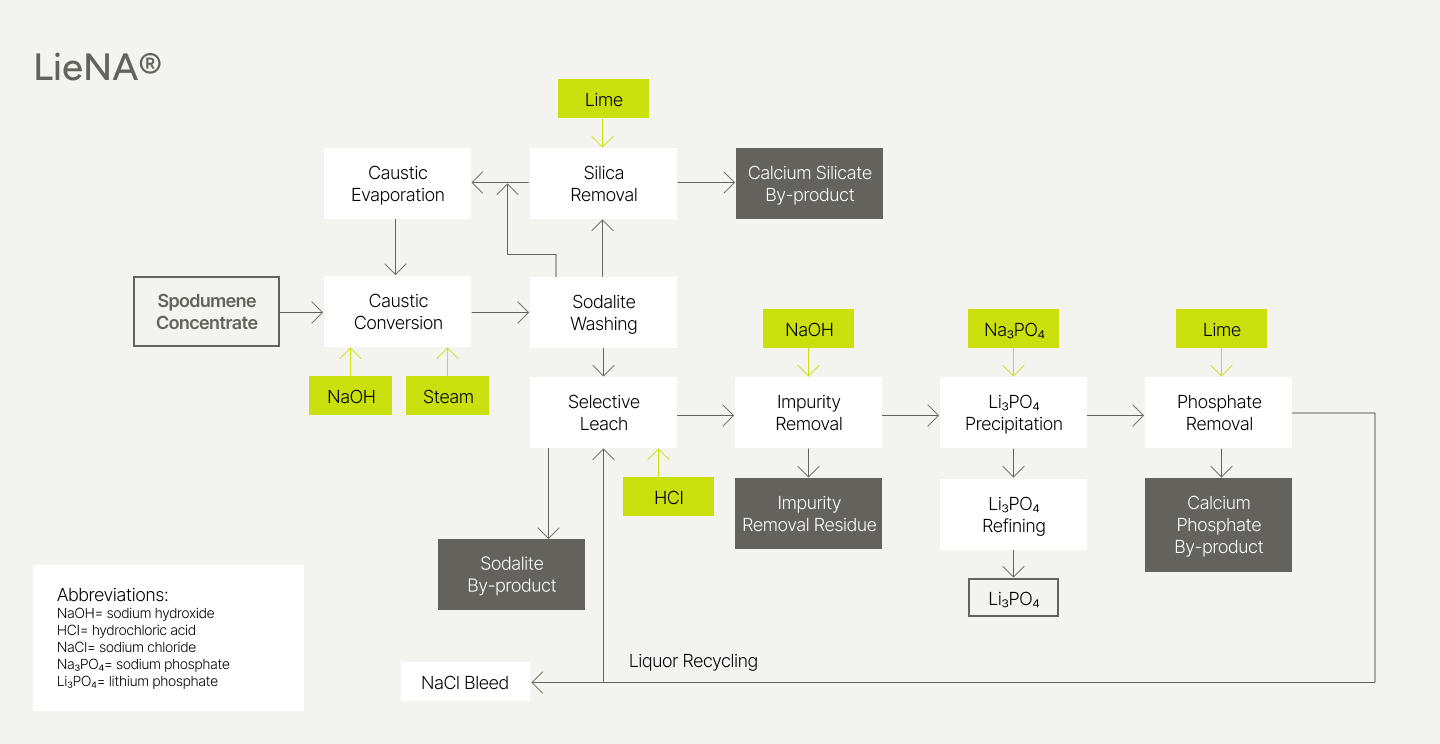

LieNA®

LieNA® is a novel process that eliminates the need for high-temperature conversion of spodumene (~1,000°C or α to β conversion). Fine spodumene reacts with caustic soda in an autoclave to form lithium sodalite, from which lithium can be readily recovered via selective leaching in weak acid.

View graph

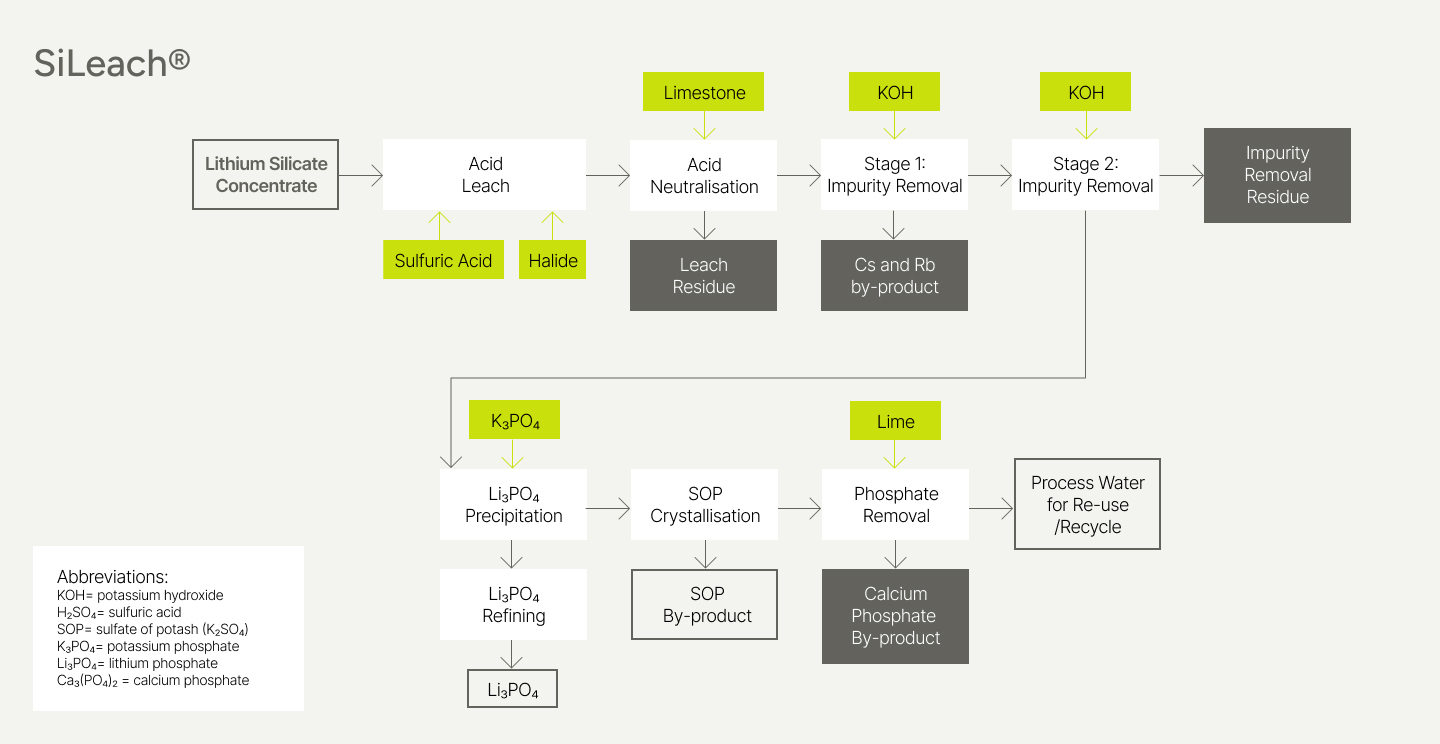

SiLeach®

SiLeach® efficiently processes lithium mica minerals, recovering valuable metals with low energy consumption and high recoveries. SiLeach® offers extensive by-product optionality, potentially becoming the benchmark for extracting lithium from mica minerals. We are looking for partners with a desire to value-add improve sustainability of mica mineral processing.

If interested, please contact us.

Collaboration with world class institutions

Since 2015, Lithium Australia has collaborated with ANSTO’s Minerals Unit to develop a world-first processing technology, LieNa® designed to extract lithium from discarded mining waste. It enables the overwhelming majority – at around 95 per cent – of lithium to be extracted from the spodumene mineral concentrate.