What we do

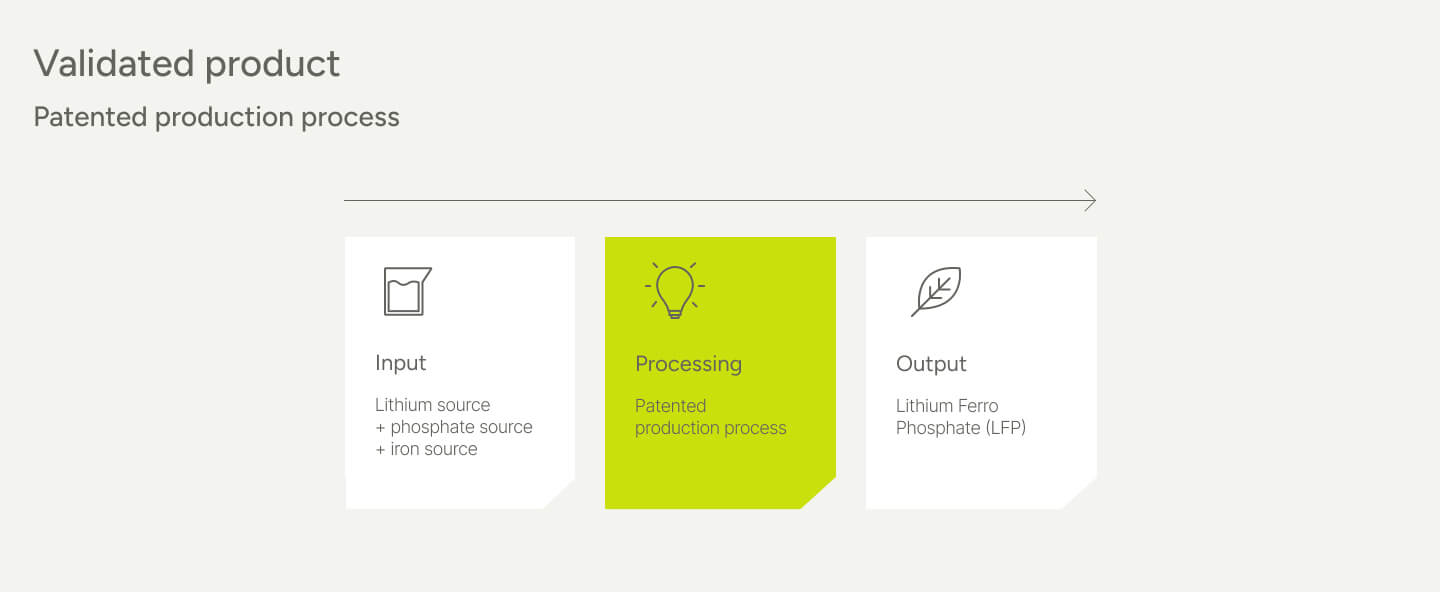

We are one of few companies outside China to successfully produce LFP. We do this by manufacturing LFP/LMFP materials using a proprietary production process. The LFP material has been verified using a commercially competitive process.

Here’s how

Our LFP products are produced by combining a lithium salt, phosphate source and an iron source which are processed through mixing and thermal treatment steps. Tested by NOVONIX Battery technology Solutions Inc., (a leading expert in battery materials research and development services), our LFP was proven to be either matched or exceeded competitor product across all testing parameters and has the potential to support for long-lifetime cell designs.

View graph

Our Process at a Glance

RC Process

Our process begins with rigorous independent assessment and validation conducted by highly credentialed chemical engineers, process engineers and battery researchers, ensuring that our products meet and exceed industry standards.

Lithium Manganese Ferro Phosphate

An emerging product offering a 15 to 20% increase in specific energy over LFP. Our RC production seamlessly transition from LFP to LMFP, ensuring readiness to meet future market demands setting us apart from other producers.

R&D and pilot facilities Brisbane

Established in 1999, acquired in 2018 as wholly owned subsidiary of Lithium Australia. Capacity to produce 2 tpa of material with 8 employees.

Our environmental impact

FAQ

Yes, VSPC IP portfolio includes:

AU 2020203801 – lithium metal phosphates (granted)

PCT/AU2021/050572 – lithium metal phosphates

PCT/AU2022/050283 – production of iron (II) oxalate

Yes, VSPC can provide samples of a range of LFP and LMFP products for assessment.